What is upcrete®?

Definition: upcrete® (“concreting upwards”).

upcrete® describes the process of concreting a precast concrete element in the die-cast, flushrising concreting method, which combines all sides smooth surfaces and production in the installation position with the greatest possible economical efficiency.

The molds are filled from below (injection) with a pump. Thereby very little air is introduced into the concrete through the filling process, so that one can work with self-compacting concrete and no additional mechanical compacting is required. Almost all limiting surfaces can be molded, merely escape openings for air are to be provided at certain points of the molded geometry, similar to what one knows from injection molding technology for plastics and metals.

Upcrete© not only revolutionizes precast concrete part production, but also sets impulses for the complete design and planning process up to production and assembly of precast concrete elements. The technology provides new - previously unknown - possibilities of prefabrication and, thus, gives stimuli to those who are creating the buildings of the future.

A great variety of products have already been manufactured using

upcrete® technology, such as for example:

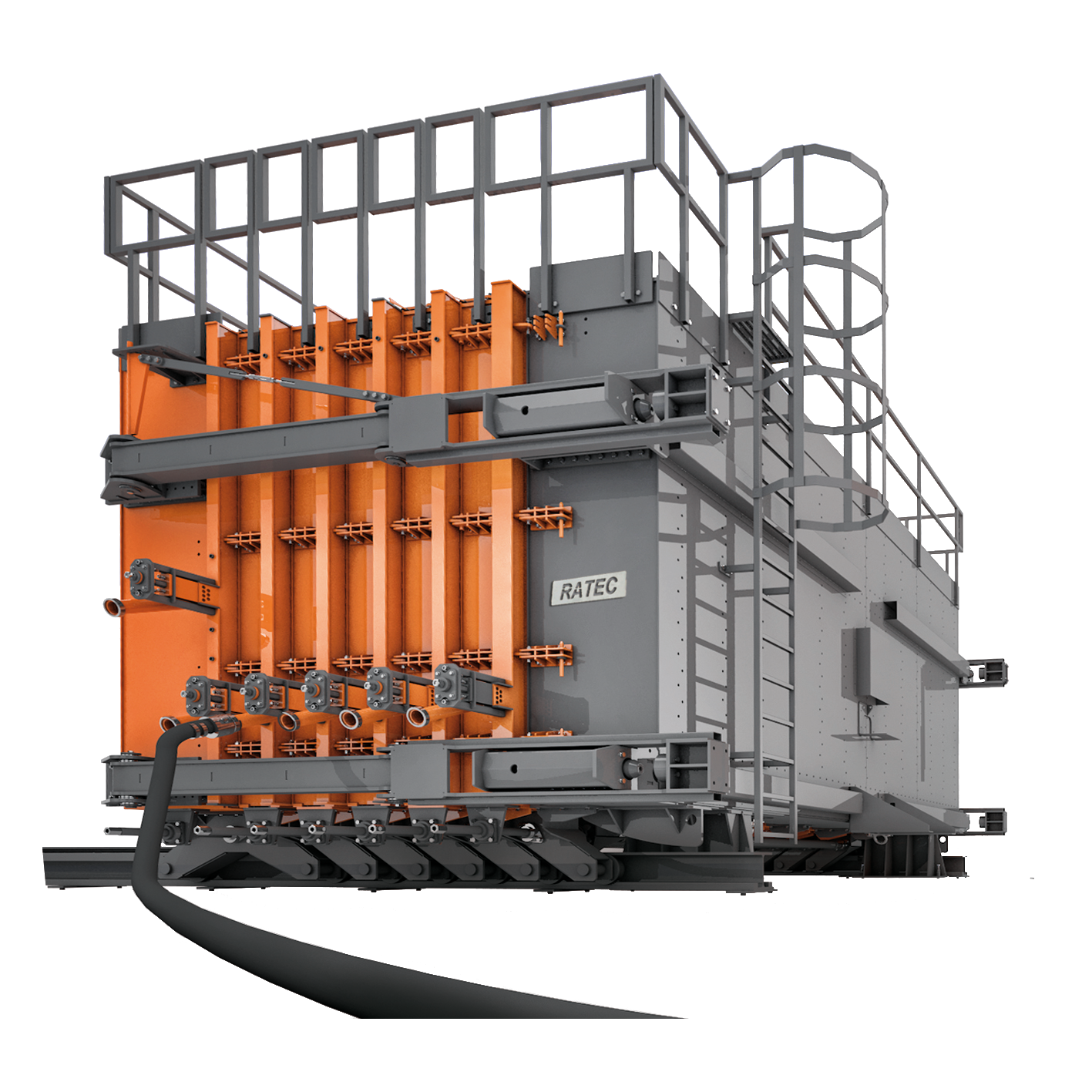

- Solid walls / sandwich walls in battery formwork

- Room modules in installation position

- Round columns, architectural columns and of trusses

- Segments

- Festival products such as waste bin boxes

- Sound barriers

- Architectural walls with matrices on both sides

- Stairs

- Roof elements

- Balconies

- Drains

- etc.

- Fewer limitations with regard to feasibility

- Maximum dimensional accuracy on the precast concrete element

- Complete filling of the most difficult geometries

- Production of complex concrete structures in the installation position

- Formwork-smooth surfaces on all sides

- No floating and smoothing of surfaces

- Minimum quantities of concrete residue

- Maximum performance

- Quiet, material-saving, efficient and employee- friendly concrete element production

- High utilization of the formwork

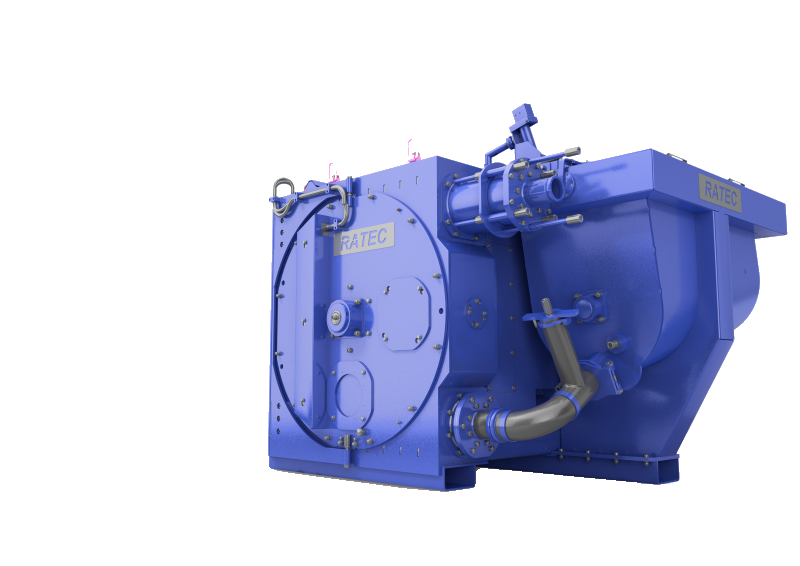

- Simple integration into existing production is possible using our concrete plant-compatible

- pump, that can be adapted to the given local concrete logistics (mixer, readymixed concrete, bucket conveyor).