Project information

Location:

Philippines

Customer product:

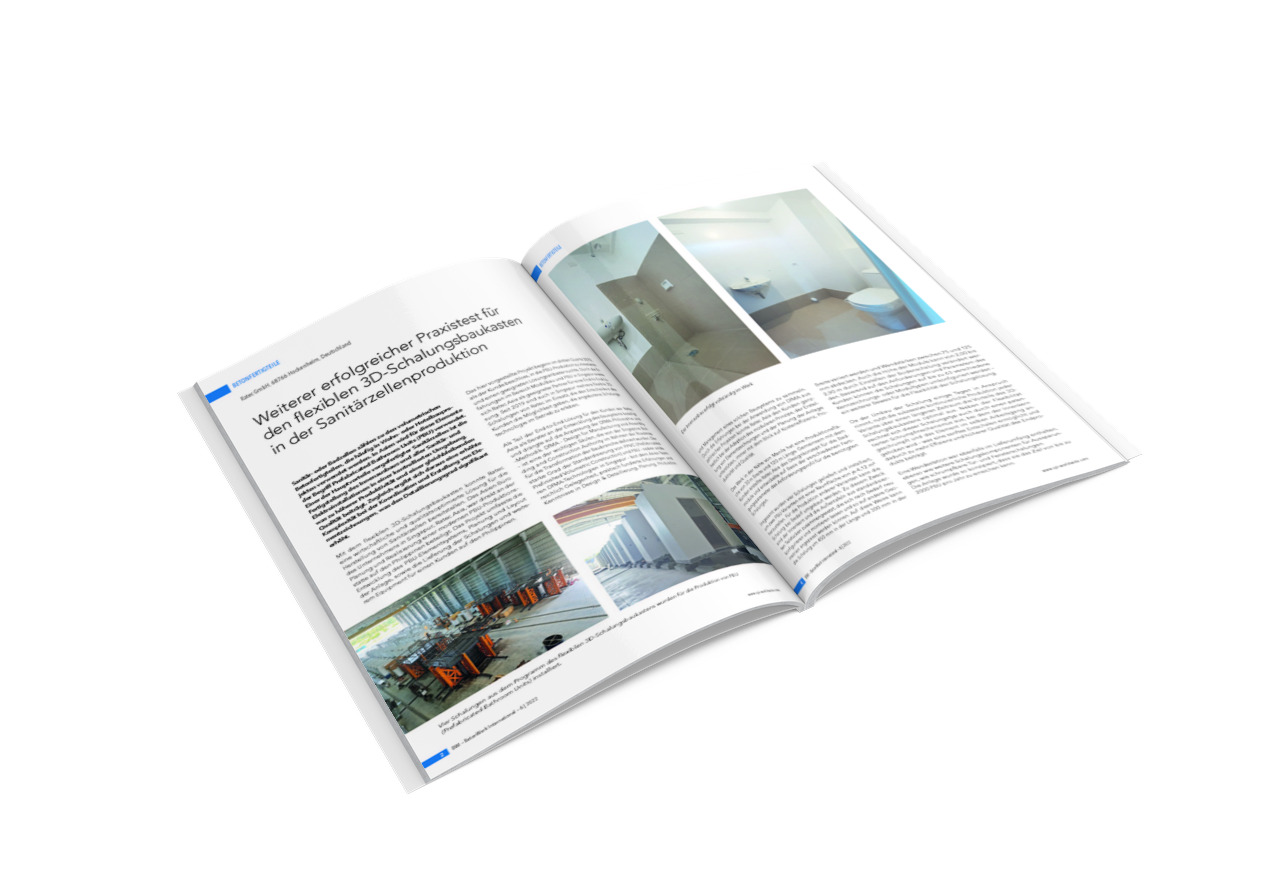

Bathroom Pods, so-called PBU (Prefabricated Bathroom Units)

Project description

The moulds are used for the production of sanitary cells, which are commonly known as prefabricated bathroom units (PBU for short) in Asia. With the 3D mould kit, Ratec was also able to provide an economical and high-quality solution for this application

Project Scope

- A total of 4 modular moulds was installed

- Through an intelligent combination of rails and movable outer panels, the formwork has a variability of 450 mm in length and 300 mm in width.

- Wall thicknesses between 75 - 125 mm can be produced in one mould

- The height of the modules can also be adjusted variably from 2.00 - 2.90 m by adapting the bottom formwork.

In addition to the formwork planning and optimization, decisively accompanied by RATEC Asia, the overall production processes were optimized as part of the installation planning, so that, for example, crane times could be optimized by the intelligent alignment of the formwork towards the turning station and, in general, emphasis was placed on minimizing process losses in the various work steps.

A total of 63 positions are available for interior finishing and completion of the bathroom cells.

Compared to conventional project-related installed moulds, the use of the 3D mould construction kit can achieve up to 77 per cent increase in efficiency, measured by man-hours, and 64 per cent increase in speed, measured by the total time for the completion of a sanitary cell.