Project information

Location:

China

Customer product:

Wind energy towers

Project description

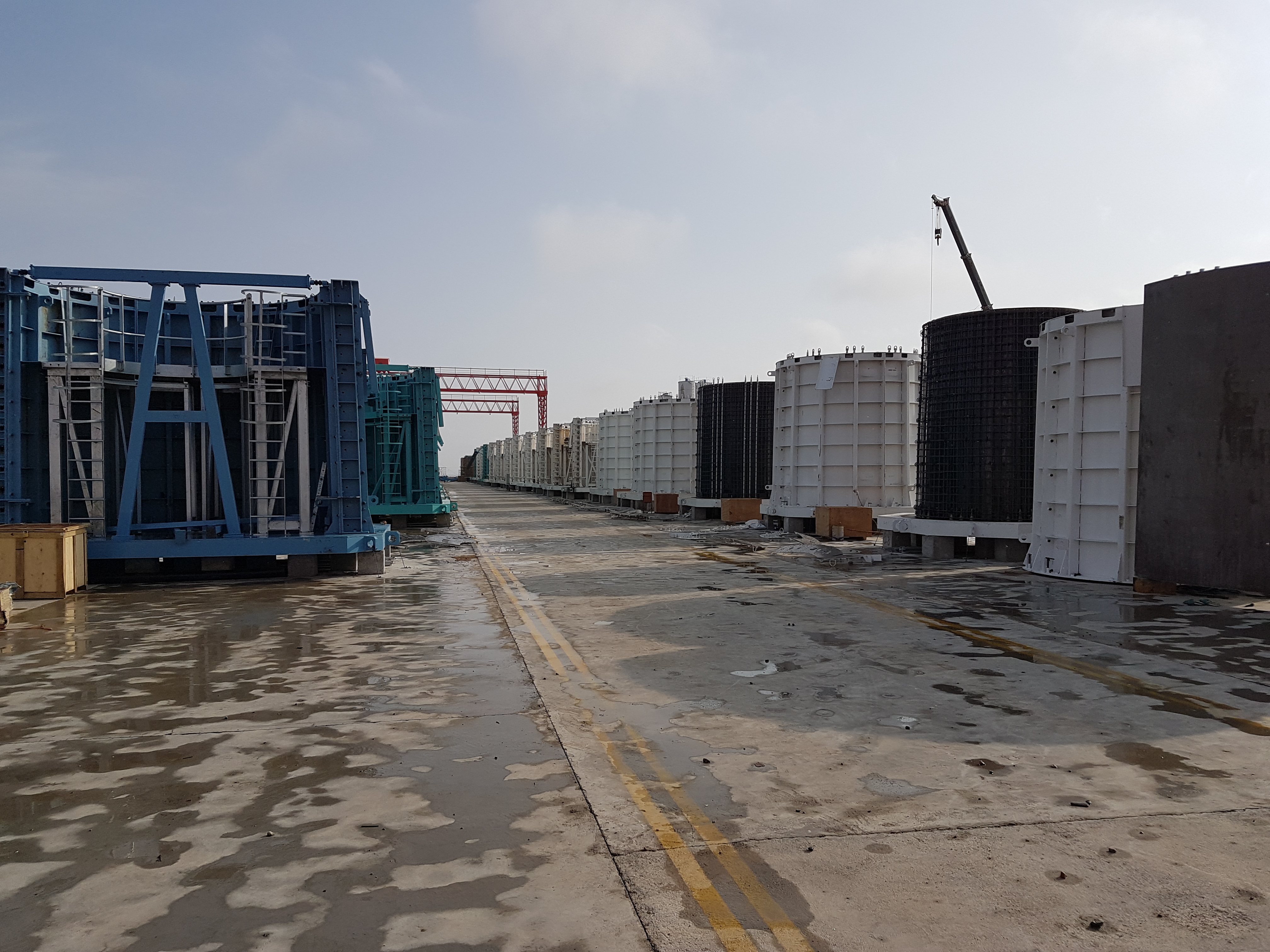

The customer develops and builds systems for generating energy from wind, photovoltaics, solar thermal energy, biomass and other alternative sources and is one of China's leading suppliers. The wind power project at that time included two production sites for the construction of 100 concrete towers, each 120 meters high, for 2 MW wind turbines of the HZ111 and GW115 types in Hami. With the previous use of steel, the masts could technically be implemented economically up to a height of 90 meters. But because the winds are most pronounced at a height of about 120 metres, it was necessary to convert the construction to prefabricated concrete elements.

Each mast consists of 30 ring-shaped reinforced concrete elements. The lower 18 sections are fabricated as semi-circular elements, the upper 12 as completely circular elements.

The customer's main challenges:

-

Efficient filling of the approx. 200 shutterings per production site

-

Very narrow reinforcement of the elements, which prevented filling from above

-

Reduction of crane capacities and time savings

-

Optimisation of the surface quality

In the first step, a suitable concrete filling connection was developed for the customer’s shuttering. With a diameter of 125 millimetres, it can easily be used wherever in-situ shutterings are filled using a construction site pump with a general hose diameter of 125 millimetres.

The customer also decided to use the upcrete® pump technology and installed a UPP100 at both production sites. The pumping stations were delivered with a special transport vehicle to ensure flawless logistics on site. The concrete was delivered via a truck mixer, which was directly coupled to the pump. As a result, no buckets were needed. This meant that the objective of reducing crane capacity and efficient filling of the shuttering could be realised. The project demonstrates that the upcrete® technology can also be easily integrated into an existing project and is directly associated with higher element quality and process optimisation. The newly developed concrete filling connection in particular could be interesting for projects where construction site pumps are used to fill closed shutterings.